Sterilization device | Autoclave

Laboklav ECO Wastewater

FAST STERILIZATION OF LARGE VOLUMES OF LIQUIDS

The destruction sterilization of large liquid containers often results in long cycle times due to the volume and the specific thermal properties of the liquids. To ensure complete elimination of all microorganisms, the sterilization temperature must be uniformly reached throughout the container and maintained for a sufficient duration. Factors such as the thermal conductivity of the container material, the heat capacity of the liquid, and its evaporation properties influence the process. Additionally, the homogeneity of the liquid and potential barriers created by the container material play a role, potentially extending the sterilization cycle.

The Laboklav ECO Wastewater series laboratory sterilizers are equipped with a sterilization chamber with a volume of approximately 140 liters, designed for the sterilization of liquid media such as cell cultures or wastewater. In exceptional cases, other items can also be sterilized, such as instruments or materials intended for non-medical purposes. (In such cases, a technician from SHP Steriltechnik AG must be consulted beforehand.)

Laboklav ECO Wastewater

powerful and reliable

The Laboklav ECO Wastewater was specifically designed for the rapid sterilization of large volumes of liquids. It allows direct filling of the chamber with up to 100 liters of liquid media, which are fully sterilized in approximately 4 hours.

Once the chamber is filled exclusively with liquid media, the chamber lid is motorized and sealed. The liquid is then heated to the required sterilization temperature and maintained for a set duration. After the sterilization phase is complete, the chamber is automatically drained using compressed air. To protect the disposal lines from overheating, tempered tap water is mixed in during the process.

up to 100 l

equipped for the sterilization of large volumes of liquids

direct filling of the chamber with up to 100 liters of liquid to be sterilized, only aqueous solutions

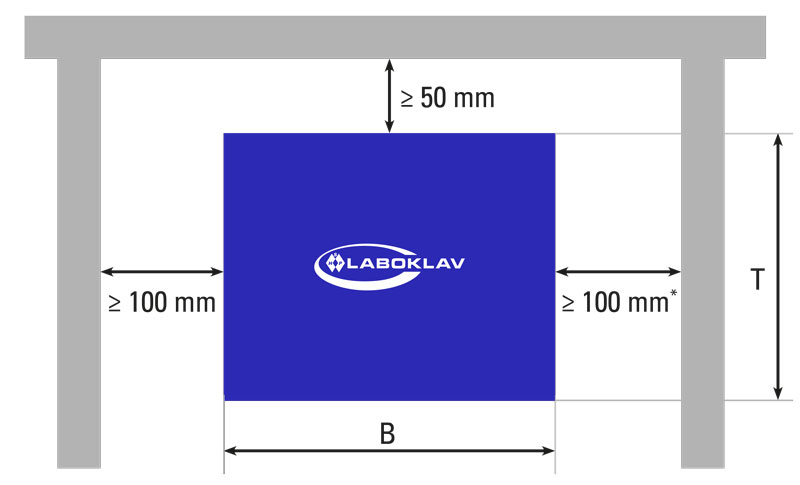

spacesaving

universally installable

Dimensions for installing:

B x H x D:

840 x 965 x 700 mm

(vertical autoclave)

variable display orientation

efficient & durable

steam generation based on the principle of direct boiler heating

Power: 6 kW

heating elements are not submerged in water (thereby extending their lifespan)

as standard

integrated dot matrix printer

exhaust air filtration

automatic emptying of chamber by injection of compressed air

- Power 6 kW

- Heating elements are not submerged in water, thereby extending their lifespan

The high-performance steam generation is achieved through heating elements that are directly in contact with the chamber floor. The sterilization medium itself is used for steam generation. Both the heating elements and the chamber are protected against dry running by over-temperature switches.

Product features and technical specifications

Sterilization chamber

directly heated by heating plates in contact with the chamber floor

Lid and Closure

Hinged lid with motorized closure, safety locking

Lid seal

T-profile seal, silicone

Temperature measurement technology

Independent PT100 sensors with compensation time T0,9= 3 s,

2-wire technology, internal resolution 0.01K, display resolution 0.1K,

calibratable Monitoring of sensor breakage and sensor short circuit

Reference sensor for liquids

Sensor as described in temperature measurement technology, permanently installed in the chamber floor

Calibration certificate according to ISO

inclusive across all devices

Pressure measurement technology

Electronic pressure sensor 0 to 6 bar, absolute pressure measurement or relative pressure measurement, programmable, monitoring of sensor breakage, resolution/display 0.1 kPa

Calibration certificate according to ISO

inclusive across all devices

Feed water supply

Manual filling, sterilization solution (aqueous) as the medium

Overtemperature protection for heating

Integrated into the heating system, monitored by the control unit.

Sterilization ventilation

Membrane filter, µ ≤ 0,2 µm, included as standard

Display of service intervals

Automatic notification via multicolor display

Microprocessor control

Control of all functions, display via multicolor display

Safety circuit

For heating and chamber pressure monitoring

Timer

Program start programmable by date and time

Audible signal

Can be activated

Interfaces

Internal RS232 for printer

External USB for printer, network, computer connection

Sterilization Programs

2 predefined programs in Level 1:

Cell culture destruction 134°C

Cell culture destruction 121°C

The programs can be individually modified (consultation with the manufacturer's service technician required!).

Custom programs (e.g. instruments 121°C, instruments 134°C, waste destruction 134°C) optionally available.

5 programs in Level 2 (Programs P6 to P10) code-protected, pre-set like P1.

CUSTOMER SERVICE is a top priority for us.

Our service network ensures short response times and competent service technicians with many years of experience in steam sterilization. Our fair prices and the service-friendly design of our devices keep costs low. We take care of your equipment.

Optional for the Laboklav ECO Wastewater

SegoSoft

SegoSoft - the fully automated, digital batch and process documentation for your sterilizers, thermal disinfectors, and sealing devices.

baskets

Grid baskets in various heights, see accessories.

DE

DE  EN

EN  PL

PL  FR

FR  ES

ES  SV

SV  NL

NL  AR

AR