Sterilization devices

Laboklav 55-195

FLEXIBLE SOLUTIONS FOR HIGH DEMANDS.

The steam sterilizer is available in two chamber diameter options: Ø 400 mm (models 55, 80, and 100) or Ø 500 mm (models 135, 160, and 195). It can be configured both horizontally and vertically, depending on the spatial constraints and requirements of the installation site. With a power range of 3.3 to 10 kW, the sterilizers are suitable for a variety of applications, from smaller to more extensive sterilization tasks. The flexible design and powerful performance make it a versatile solution in sterilization technology.

Selected chamber diameter:

Laboklav 55, 80 and 100

Steam sterilization with chamber volumes from 55 to 100 liters

These three autoclaves with chamber volumes of 55, 80, and 100 liters provide optimal solutions for laboratories with varying sterilization requirements. These autoclaves in the series feature an integrated and performance-optimized steam generator with a power of 6,6 kW, which ensures shortened batch times through very rapid heating of both the autoclave chamber and the load.

versatile

equipped for the sterilization of liquids, solids (no narrow hollow bodies), and easily vented waste

compact design

available in various color options

adjustable

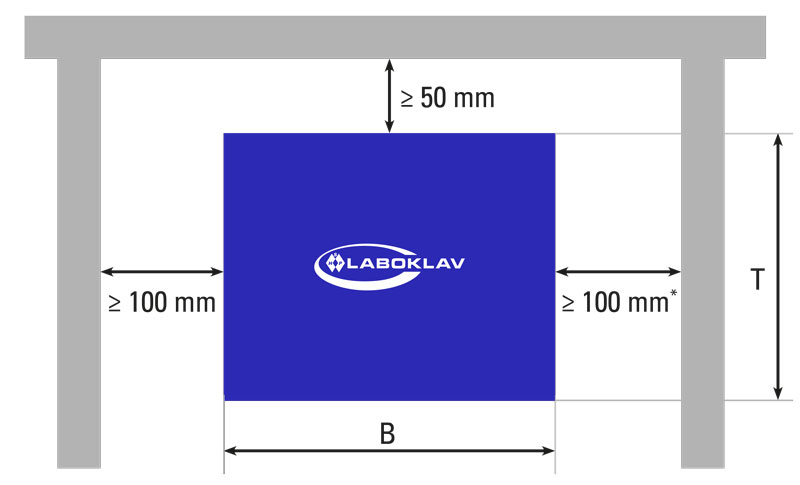

can be configured horizontally or vertically

available as a freestanding unit or a tabletop unit (conversion possible at any time)

efficient & durable

standard steam generator

Power 6,6 kW

integrated, high-performance steam generator that enables shortened batch times through rapid heating

excellent

True 32-bit system with large multicolor touch control panel and internal 16 GB memory

- High loading volume

- Low electricity costs

The assumption that a large chamber automatically means a high loading capacity is widespread. However, especially when loading with liquids in 1-liter bottles, this is not always accurate. The more compact the device, the more expensive stainless steel is saved, and less heating power is required to bring the sterilization goods to the required temperature. During the cooling phase, only the energy that was previously introduced needs to be removed. The device is equipped with heating power that is optimally matched to the chamber size and processes. This adjustment of heating power leads to significant savings in operating costs and faster processes.

Product features and technical specifications

Sterilization chamber

Direct steam heating by integrated steam generator, indirectly steam heated via double jacket during preheating and drying

Lid and Closure

Hinged lid with motorized closure, safety locking

Lid seal

T-profile seal, silicone

Temperature measurement technology

Independent PT100 sensors with compensation time T0.9 = 3 s,

2-wire technology, internal resolution 0.01K, display resolution 0.1K,

calibratable Monitoring of sensor breakage and sensor short circuit

Reference sensor for liquids

Temperature sensor as described in temperature measurement technology with flexible measuring line, provided as standard in all models.

Calibration certificate according to ISO

inclusive across all devices

Pressure measurement technology

Electronic pressure sensor 0 to 6 bar, absolute pressure measurement or relative pressure measurement, programmable, monitoring of sensor breakage, resolution/display 0.1 kPa

Calibration certificate according to ISO

inclusive across all devices

Feed water supply

Integrated tank, integrated degassing, automatic filling and refilling of the tank, manual filling possible

Feed water pump

35 l/h, automatic feed from integrated storage tank

Water level control

Level sensors for low level and max level

Overtemperature protection for heating

2 independent systems: Temperature control of the heating via PT100, overtemperature protection by two separate overtemperature protection switches, one with autoreset and one without autoreset (unlockable only by a technician)

Sterilization ventilation

Membrane filter, µ ≤ 0.2 µm, included as standard in all models

Display of service intervals

Automatic notification via multicolor display

Microprocessor control

Control of all functions, display via multicolor display

Safety circuit

For heating and chamber pressure monitoring

Timer

Program start programmable by date and time

Audible signal

Can be activated

Interfaces

Internal RS232 for printer

External USB for printer, network, computer connection

Sterilization programs

10 predefined programs in Level 1:

Program assignment depends on the configuration level. The programs can be modified individually.

10 programs in Level 2

Programs P11 to P20

Code-protected, pre-assigned like P1

2 test programs (P 21: Bowie & Dick test, P22: Vacuum test, only in vacuum versions)

additional special programs available upon request

CUSTOMER SERVICE is a top priority for us.

Our service network ensures short response times and competent service technicians with many years of experience in steam sterilization. Our fair prices and the service-friendly design of our devices keep costs low. We take care of your equipment.

Configurations and Loading Capacity

DE

DE  EN

EN  PL

PL  FR

FR  ES

ES  SV

SV  NL

NL  AR

AR